What is Arc Flash? – An Introduction

An Arc Flash is a rapid release of energy that occurs because of an arcing fault caused by a short-circuit between two energised conductors. Except from the laser, the electrical arc that occurs between these energised conductors is the hottest known source on earth with temperatures reaching up to 35,000 degrees Fahrenheit. Four times as hot as the sun’s surface. There is also the risk of air ionizing which makes it a harmful gas when inhaled.

Due to the extreme temperature, there is a high risk of clothing igniting and causing severe skin burns. There is also potential for injury to happen due to inhaled gases, blinding light, flying shrapnel, shock waves and thermal radiation.

How do I protect myself against it? This article will answer this question and also show you what we do at Reece Safety to ensure our customers are working in a safe environment.

What Causes Arc Flash?

An arc flash could be initiated through accidental contact, equipment which is underrated for the available short circuit condition, contamination or tracking over insulated surfaces, deterioration or corrosion of equipment and its parts, as well as other causes.

Arc Flash Guidance

Regrettably, it often takes an incident to prompt a reaction to review internal electrical safety measures. Often overhasty decisions are made that are not the best in the long run. We help you to avoid these mistakes which can often be expensive. To avoid this, you need to know how to go about getting the correct level of protection.

Reece 5 Point Plan to Reduce Arc Flash Hazards

At Reece we use a 5-point plan that is trusted and has helped us guide many customers in a safe working environment.

The first step is to identify all work places with an arc flash hazard.

The second step is for a qualified professional electrical engineer to undertake an arc flash study. In order to perform the arc flash study a short circuit and coordination study must first be performed, or the results of these studies must be available to the engineer performing the arc flash study.

The initial work is to avoid the need for entry and then one must identify methods to reduce the risk – possibly even upgrading the switching gear for modern equipment with a lower incident level or arc flash containment.

From the study, the next step is to assess the risks, and identify what category the hazard risk is, ranging from 1 to 4, or even extreme danger and this will give an indication of what arc flash PPE clothing is required (See Table below).

It is important to remember that new regulation now states that you can no longer simply add the arc-rating of layers together to legally have a result of the protection, as you now (as of 2017) need a test proven ATPV value and this has been done to eliminate any risk associated with poorly judged calculation.

|

Category of Hazard |

PPE required |

Min. Arc Rating |

|

1 |

Arc rated clothing

Protective equipment

|

4 Cal/cm² |

|

2 |

Arc rated clothing

Protective equipment

|

8 Cal/cm² |

|

3 |

Arc rated clothing

Protective equipment

|

25 Cal/cm² |

|

4 |

Arc rated clothing

Protective equipment

Leather footwear. |

40 Cal/cm² |

|

Extreme Danger |

None available. |

|

Once the hazard risks have been identified, new safety measures will be established in correlation to the guidance and current electrical safety measures will be updated. This will include the use of appropriate clothing, gloves, footwear and face protection in accordance to the hazard risk category.

The final step is then to train staff to meet the new safety measures and how to successfully use the protective clothing and equipment.

Arc Flash Risk Assessment

Working safely in a high voltage environment involves fundamental legislation, varying levels of protection rating and the real threat of serious injuries or even fatalities. This means you need to ask yourself, how sure are you that you are safe at work? Also, are the procedures currently chosen on-site good enough?

A risk assessment is a legal requirement under Management of Health and Safety at Work Regulations 1999. Secondly, there are the practical benefits you gain. There is a lot of PPE on the market, with varying levels of protection which can be misleading without the knowledge.

The natural thought process would be to purchase the highest level of protection to cover all aspects, however this can be expensive and there are other aspects to PPE, such as ergonomics and user comfort. Some higher quality garments will offer a lower total life as users will prefer them and the fabrics will have better wear characteristics.

Arc Flash Study

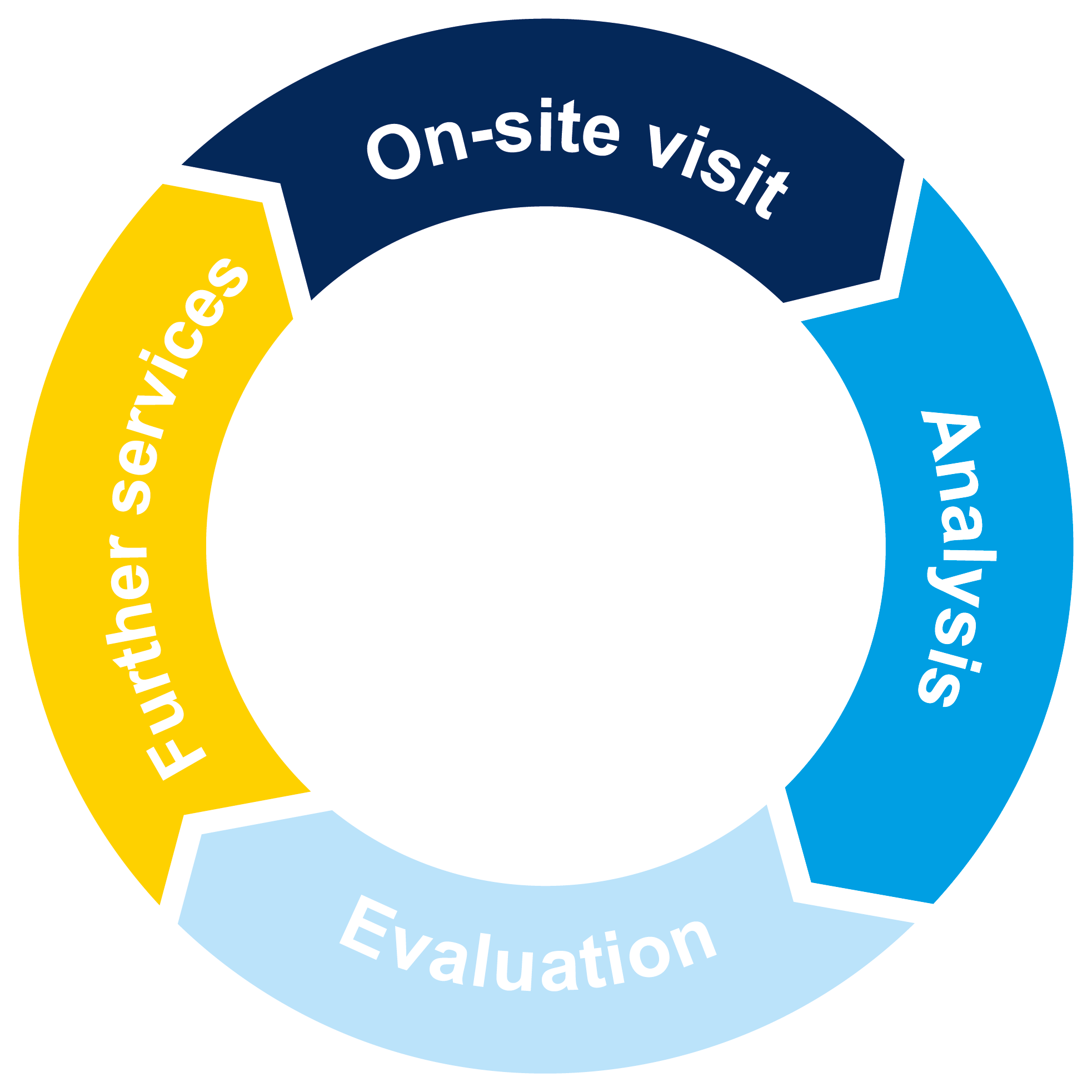

To ensure all employees are optimally protected, an optimal risk assessment is required. At Reece Safety we use a four step process that will take you from unsure and wary to educated and most importantly, safe.

The four step process starts with an on-site assessment which will determine the actual state of procedures in place and also determine the targeted state of procedures to be implemented.

Following this, analysis of data collected takes place, including an incident energy calculation, a measure which has been developed to assess electric arc flash events and is the energy measured on a surface at a specified working distance from the arc flash location.

In evaluation, you will receive a recommendation for improvement and also a final report which will include the requirements needed to maintain a safe working environment.

Further services include the creation of a personalised protective concepts such as, procedures, PPE and training required.

Arc Flash Training

Working in an arc flash environment and not competent could result in a fatality at work.

Reece provides training courses to range from basic understanding of the arc flash risks and the use and care of appropriate PPE through to the Arc Flash Risk assessment and PPE Category selection.

We can also create and deliver bespoke training packages to suit the specific environment and hazards in your workplace. These bespoke courses can take up to 8 learners through very detailed arc flash risk calculations if needed or simply link into the calculated risk level and appropriate PPE being issued with use and care instructions. Current COVID restrictions have reduced this level to 4-5 per session.

The six questions you must ask yourself to ensure that your last line of defence is enough:

- Do you understand the hazards of an arc flash?

- How do you mitigate the risk using the hierarchy of hazard risk controls?

- Do you have a best practice risk assessment?

- Do you understand the legal meaning of NFPA 70E and IEEE 1584?

- What is the difference between open arc-test and box test and how does it affect you?

- How right is your arc flash PPE according to you field of activity?

If you are unsure on any of these questions, there are two awareness courses available at Reece Safety, Arc Flash Awareness for Managers and an Arc Flash Awareness Course.

US

US UK

UK